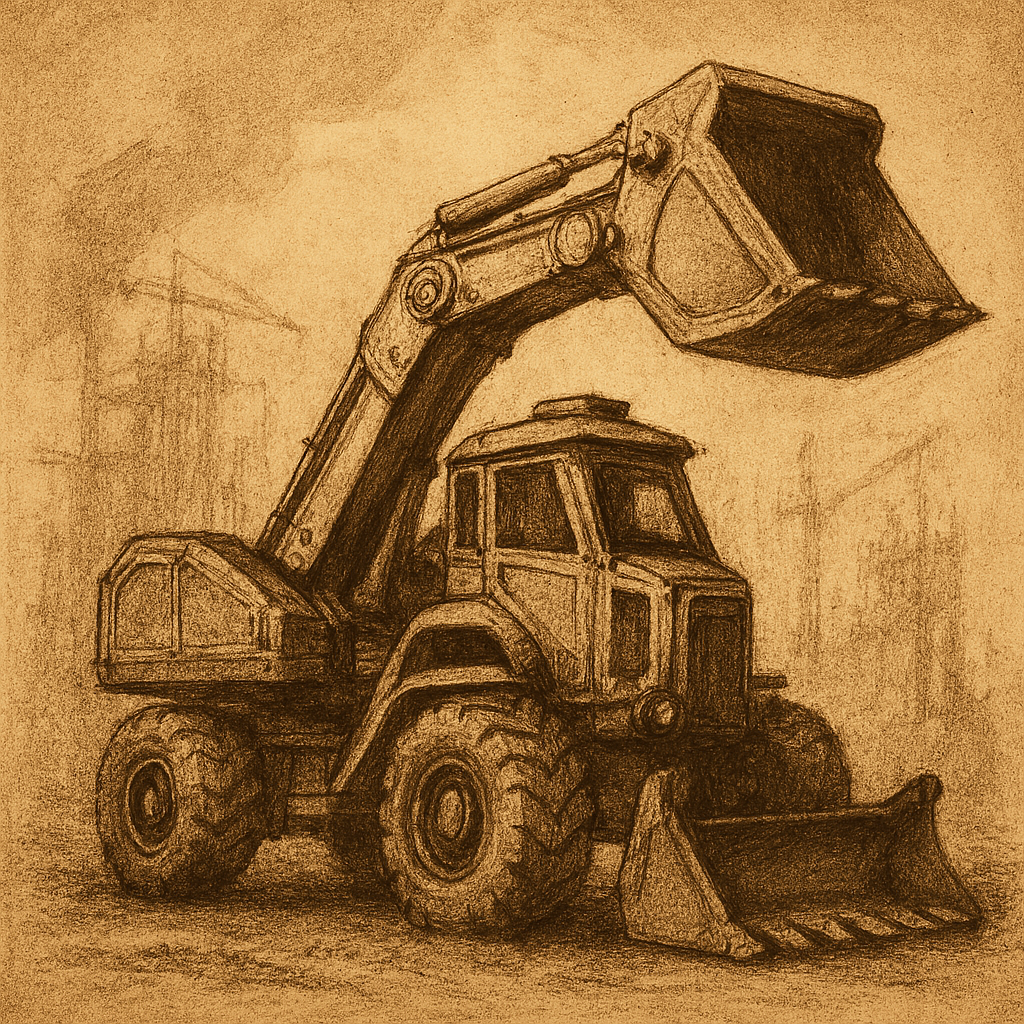

The good old tractor-loader-backhoe (TLB) is as much a part of South African construction industry as biltong and braais evolving from a rudimentary m

The good old tractor-loader-backhoe (TLB) is as much a part of South African construction industry as biltong and braais evolving from a rudimentary machine to sophisticated machines designed for a wide range of purposes.

Back in the day the first TLB’s were produced as an idea to put digging power on the back of a loader and began evolving as new and different purposes were found on sites. Today, they fulfil many roles and have become multi-role machines with the ability of one operator doing the job of two.

That versatility is exactly why TLBs still make sense on concrete batch plants, precast yards and small to medium construction sites across South Africa where they load, lift, dig, break and tow.

A bit of research reveals that the backhoe’s origin is incremental. In the late 1940s engineers fitted swing-frame hydraulic diggers to tractors. That basic concept evolved into a dedicated backhoe loader in the 1950s and 1960s as manufacturers integrated loader and backhoe functions into a single chassis. From those early patents grew the modern TLB: mobile which is hydraulically driven and fitted to do multiple tasks with a single powertrain.

In the concrete industry the TLB is in its element. Concrete batching plants are material-handling centres. Aggregates, sand, gravel and recycled concrete need moving between stockpiles, hoppers and conveyors. Silos demand housekeeping and bays require routine cleaning and quick repair work. A TLB answers this mix of chores because it combines a front loader for fast scooping and charging of hoppers with a rear digger that can reach or dig drainage and service work.

Where space is tight a TLB’s compact footprint and ability to move quickly on wheels beat the logistics of bringing in separate wheel loaders and small excavators. Practical benefits for batching plants include quicker hopper-charging cycles, faster clean-ups between mixes and immediate on-site maintenance capability.

In smaller concrete yards this “front-end loader / rear-end excavator” combination reduces handling stages, simplifies logistics and lowers the number of operators on site. This can amount to a reduction in labour on site where costs are high and skilled operators are scarce.

The TLB’s utility depends on its aftermarket use with a range of quick-couplers, buckets, augers, hydraulic breakers (hammers), cold planers, rakes, thumbs, grapples, brooms, pallet forks and compaction wheels among others. It is little wonder that building contractors find such a versatile machine indispensable on site.

Attachment choice changes job scope and can change with different stages of construction or in the batching plant for different products being manufactured. For example, high-capacity front buckets speed hopper charging, trenching buckets increase excavation precision, hydraulic thumbs and grapples tidy demolition and handle reinforcement. For concrete environments the specialised buckets (high-capacity, wear lined) and brooms for clean-down are particularly valuable.

Demolition and slab work push TLBs beyond digging. Most modern backhoe loaders supply hydraulic flow and dedicated take-offs (power-take-off arrangements or auxiliary hydraulics) to operate hydraulic breakers and other powered attachments. Contractors commonly fit hammers for breaking old concrete slabs, asphalt and footing during servicing or reclamation work at plants.

Using a hammer from a TLB gives a fast mobile demolition solution where the operator positions the machine, stabilises the rear outriggers and powers the breaker via the TLB’s auxiliary hydraulics. OEMs routinely show backhoes using hydraulic hammers for pipe bedding and slab removal — a standard configuration on many yard and municipal jobs.

Backhoe loaders span compact small to heavy construction models. In concrete and construction mid-size machines (5–9 tonnes) handle most batching-plant and site tasks. Large “heavy frame” TLBs push 9–11.5 tonnes and carry 1.0–1.4 m³ loader buckets and extendible backhoe booms for deeper digging.

Two global models show the top end of the spectrum: Caterpillar’s 444 series and JCB’s 4CX/5CX ranges represent the class of the largest contemporary backhoe loaders, with operating weights approaching 9–11 tonnes, loader bucket volumes around 1.2–1.4 m³ and digging depths in the 4–5 m range. These machines also deliver road speeds of about 40 km/h and substantial hydraulic flow for heavy attachments.

Work-rate example

A well specified heavy TLB with a 1.3 m³ loader bucket can cycle aggregate into a hopper quickly with several full loader cycles per hour depending on stockpile geometry and operator skill. On the backhoe side, with an extendible dipper and efficient bucket, a single operator can dig and load several metres of trench per hour (conditions dependent). When fitted with a hydraulic hammer, the same machine will break thin concrete slabs at a rate much lower than an excavator with high-flow hydraulics, but it offers unmatched versatility. One machine completes demolition and material handling without extra plant.

Buy, run and maintenance costs decide many equipment choices. A TLB typically costs less than the combined price of a medium excavator plus a medium wheel loader. In South Africa, market listings show new heavy TLBs the banking-size range of roughly R1.0–R1.5 million (new or late-model used figures vary). Popular used JCB 3CX machines appear in classifieds typically under R1m depending on hours and model. By contrast, a medium wheeled loader plus a compact excavator together carry a higher upfront cost and require two operators.

Rental or hourly rates also differ with specialised excavators (and large wheel loaders) attracting higher hourly hire and fuel consumption. For contractors who need wide capability but cannot justify two machines a TLB is often the lower total-cost-of-ownership route.

Ask distributor or plant hire operators and they will tell you that there are clear limits. If the work requires deep trenching, continuous digging or high-flow hydraulic breakers a tracked excavator will be faster and more fuel-efficient. If a plant needs very high hopper throughput (hundreds of m³/hr), a dedicated wheel loader with larger bucket capacity will move material faster. The choice is about matching machine capability to the duty cycle: TLBs excel when variability and versatility outweigh the need for specialised throughput or extreme digging depth.

South Africa’s market supports global OEMs and regional dealers. Major suppliers and dealer networks include Caterpillar (through Barloworld in Southern Africa), JCB (local dealers and Bell Equipment distribution in some channels), LiuGong (through ELB Equipment), Kubota (and the Kubota/Escorts branded TLBs through Smith Power Equipment), Bell, Case/New Holland and a range of Chinese and Indian brands for lower-cost alternatives.

Dealers maintain parts inventories and attachment supply chains which is an important consideration for concrete plants that cannot tolerate long downtime. For serious buyers, dealer support and proximity often matter more than a few rand on the initial purchase price.

<

Specifying a TLB for a concrete plant

Buyers should be systematic: specify bucket volumes appropriate to the hopper throat, choose a heavy-duty front bucket and wear liner for abrasive aggregates, pick a backhoe configuration (standard or extendible) to match trenching depth and ensure sufficient auxiliary hydraulic flow for breakers or planers. Quick-couplers and heavy-duty undercarriage reduces downtime and a good cab with climate control improves operator uptime. Finally, discuss service intervals and guaranteed parts availability with the dealer as plant throughput depends on machine uptime.