JESSOP & ASSOCIATES PTY LTD, the only South African based equipment manufacturer specialised in concrete roof tile plants, has satisfied this industry

JESSOP & ASSOCIATES PTY LTD, the only South African based equipment manufacturer specialised in concrete roof tile plants, has satisfied this industry and its market for more than four decades.

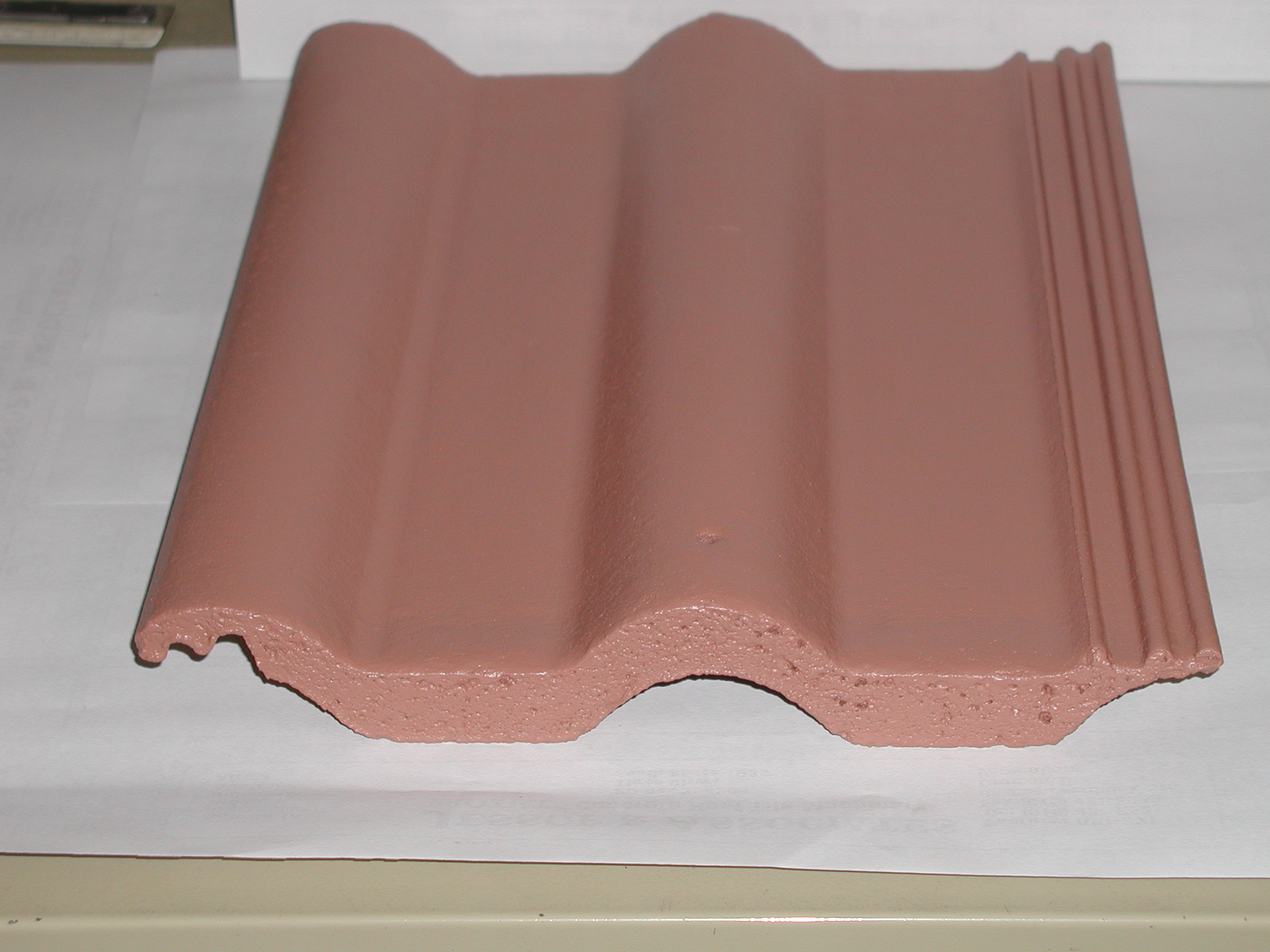

Since launching, the PROTILE® Double Roman tile profile, as an SABS approved design, in 1986,

Jessop & Associates went on to design and launch into various concrete roof tile markets the well-known PROTILE® TUSCAN tile, loved by local and Brazilian architects and extensively manufactured by Jessop & Associates clients, then followed by the PROTILE® SHINGLE tile profile developed for the Australian market now popular in South Africa and across borders.

• HIGH SPEED EXTRUSION

Jessop & Associates from its factory in the Vaal Triangle, is the only equipment manufacturer in the whole of Africa capable of manufacturing and installing as turnkey projects the

specialised plant and equipment for high-speed continuous extrusion of concrete roof tiles, at speeds up to 100 tiles per minute. In fact, there are probably only three companies world wide with this capability, with the other Companies only having local agents who import such equipment.

• PASSING ON THE KNOWLEDGE

The founder of Jessop & Associates, Grahame Jessop, started his career in the concrete roof tile industry with a UK based company in 1978. After completing four major tile plant projects with this company, he launched Jessop & Associates in 1985. Now, with over 130 tile plants in 36 countries, the PROTILE® Equipment Brand is synonymous with quality in many parts of

the world. Passing on this vast experience has been an ongoing journey undertaken by Grahame Jessop, significantly through the presentation of more than 12 seminars and workshops both locally for the African market and internationally in South America

and Australia. The South African seminars are frequently attended by concrete roof tile manufacturers from foreign countries, flying into South Africa specifically to attend these seminars. The extensive seminar manual and notes became the industry “reference book” in many instances.

Ronald Jessop, also a Director of Jessop & Associates, and an expert in the extrusion process has been using his professional engineering expertise in innovative product design and development for over two decades.

• RAW MATERIAL ANOMALIES

A good understanding of the specific characteristics of the raw material requirements for the extrusion process is fundamental to success in this industry, and for this reason a full day of the three-day seminars is dedicated to exploring and demonstrating these criteria. During this time, it is shown that the aggregate gradings alone are of relatively little value.

Crucial is the mineralogy together with particle shape and texture, interstitial moisture, and water requirements of the aggregates.

This information together with a WET grading analysis resulting in a more relevant FM calculation, minus 75-micron content and characteristics and flow properties tested using a

flow cone apparatus, enables an optimal mix blend design for extrusion to be achieved. The concrete roof tile industry in the modern roofing market is very demanding, requiring the expert assimilation of this data to enable a competitive edge in a market where the difference between an aggregate/cement ratio of 3.85:1 and 3.95:1 could make a significant difference to margins.

• FORMING THE ROOF TILE

Using the critical mix design parameters, the high-speed extrusion process requires precise control of concrete flow in the extrusion head. The PROTILE® Double Roman Mk VI aluminium pallet is a far cry from the earlier Mk II Double Roman pallet of the 1980’s.

Since the bottom surface of the concrete roof tile is completely formed via the detailed design of the aluminium pallet, it goes without saying that a lot of the success in terms of “compaction” or extrusion density lies in the pallet design. The material flow enabled by the

design of the aluminium pallet is of course critical. This becomes more apparent at the higher extrusion speeds. These high production tile plants need to create a fine balance between tile body thickness, typically, within a tolerance of 10.5mm to 11mm ± 0.25mm, and tile

depalleting strength which could be as low as 900 Newton at 24 hours testing.

• SUCCESS OF ALUMINIUM PALLETS

Jessop & Associates budget approx. 12 months for the development of a new aluminium pallet design, followed by a further six months for manufacturing the high-pressure die needed to cast these pallets.

The risk is high as is the capital expenditure involved. Due to the extreme extrusion forces, optimal strength to mass ratio is crucial for the pallet.

Only aluminium achieves this, with no flexing of the pallet, in a cost-effective manner, borne out by the fact that after extensive research 95% of the industry uses aluminium pallets worldwide. Should flexing occur as it does with steel pallets, then the tiles formed will not conform to stringent roofing criteria. It will “rock” and have varying overlapping and interlocking gaps. The less known advantage of the aluminium is the formation of aluminium stearates during the extreme extrusion pressure to form a physical interface barrier between concrete and pallet, thus assisting high speed depalleting of tiles from pallet.