Compaction is one of the most critical and often underestimated aspects of paving construction in South Africa whether one looks at small projects suc

Compaction is one of the most critical and often underestimated aspects of paving construction in South Africa whether one looks at small projects such as residential walkway or industrial yards.

It is a fact that the long-term performance of any paved surface depends largely on how well the underlying layers are compacted. Failures such as settlement, rutting, uneven surfaces and edge collapse can almost always be traced back to inadequate compaction rather than the paving units themselves.

Reputable paving companies’ practice generally aligns with SANS and municipal specifications which require the upper pavement layers beneath paved surfaces to achieve a minimum of approximately 95% Modified Maximum Dry Density, depending on the traffic class and material type. These requirements apply equally to pedestrian pavements and motor traffic applications, with the difference lying mainly in layer thickness, material grading and compaction effort.

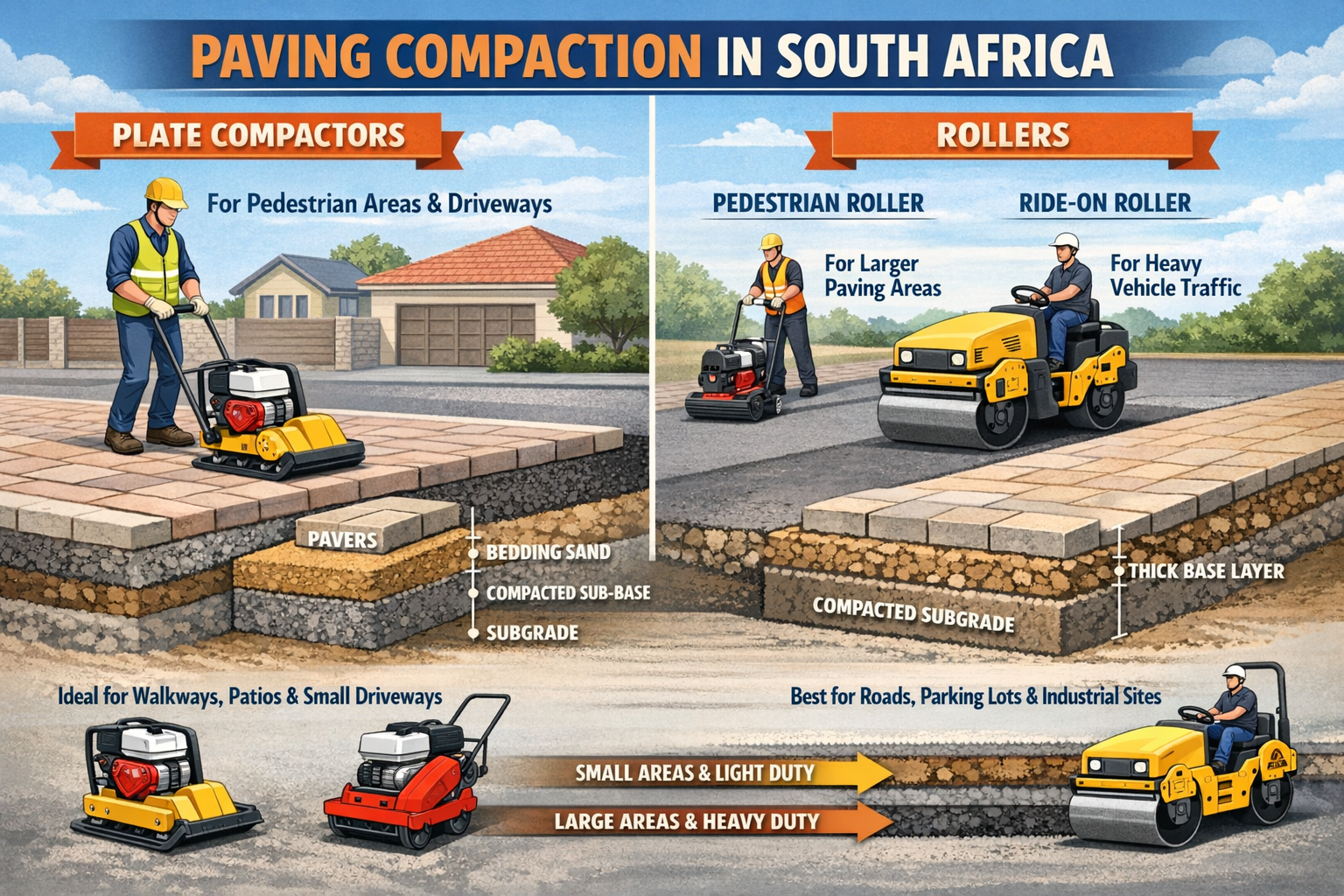

At the centre of these is the compactor. Plate compactors are walk-behind vibratory machines designed to densify granular materials such as crushed stone, gravel and bedding sand. They work by transmitting vibration and static load through a flat steel plate, rearranging particles and reducing voids. For paving applications plate compactors are particularly well suited to compacting sub-base layers in controlled thicknesses, as well as compacting bedding layers prior to laying pavers.

In pedestrian paving, such as sidewalks, patios and courtyards, plate compactors are often the primary compaction tool from start to finish. These applications typically involve thinner layers and lower load demands making single-direction or reversible plate compactors ideal. Their manoeuvrability allows effective compaction along edges where larger machines struggle to achieve uniform density.

For residential driveways and light vehicular traffic, plate compactors remain effective provided the base layers are constructed in thinner lifts and compacted in multiple passes. Heavier plate compactors with higher centrifugal force are generally preferred in these situations to ensure sufficient energy transfer into the material. Many contractors also use protective rubber mats on plates to compact pavers after laying, reducing the risk of surface damage while still seating the blocks properly.

South Africa has a wide range of plate compactors available through both purchase and hire channels. These machines are widely supported, easy to maintain and suitable for most granular materials used in paving construction locally. For cohesive or clay-rich soils, however, plate compactors are less effective and tamping rammers are often used to achieve deeper compaction before a granular layer is introduced.

While plate compactors dominate smaller paving projects there are clear situations where a roller becomes the more appropriate choice. As paving areas increase in size or where motor traffic loading becomes more significant, pedestrian or ride-on rollers offer advantages in both efficiency and consistency. Rollers apply compaction over a wider footprint, delivering more uniform density across large open surfaces such as parking areas, access roads and commercial yards.

Pedestrian rollers are commonly used on medium-sized paving projects where productivity becomes important and where surface regularity must be tightly controlled. For heavier motor traffic applications particularly where thicker base layers are required ride-on rollers provide deeper and more reliable compaction that aligns better with civil engineering specifications. In these cases, plate compactors are still valuable for edge work and confined areas but should not be relied on as the sole compaction method.

The key to selecting the right compaction tool lies in understanding the material type, layer thickness, area size and expected traffic load. Granular materials compact well under vibration, but they must be placed at the correct moisture content and compacted in layers that match the capacity of the equipment. Attempting to compact thick layers in a single pass regardless of the machine used is one of the most common causes of paving failure.

In practical terms plate compactors are best suited to pedestrian paving, residential driveways and smaller commercial areas where access is restricted and precision is required. Rollers should be considered where areas are large, production speed matters or structural performance under vehicle loading is critical.

Ultimately, good paving performance must match the compaction method to the application. When the right equipment is selected and used correctly paving systems deliver the appearance and service life that South African standards are designed to achieve.