In the world of construction, especially in South Africa where site conditions often vary dramatically, the humble water level remains one of the most

In the world of construction, especially in South Africa where site conditions often vary dramatically, the humble water level remains one of the most reliable and cost-effective levelling tools available. While laser levels and digital instruments dominate large-scale projects, the water level continues to be a trusted instrument for smaller residential and general building work — but only when used correctly.

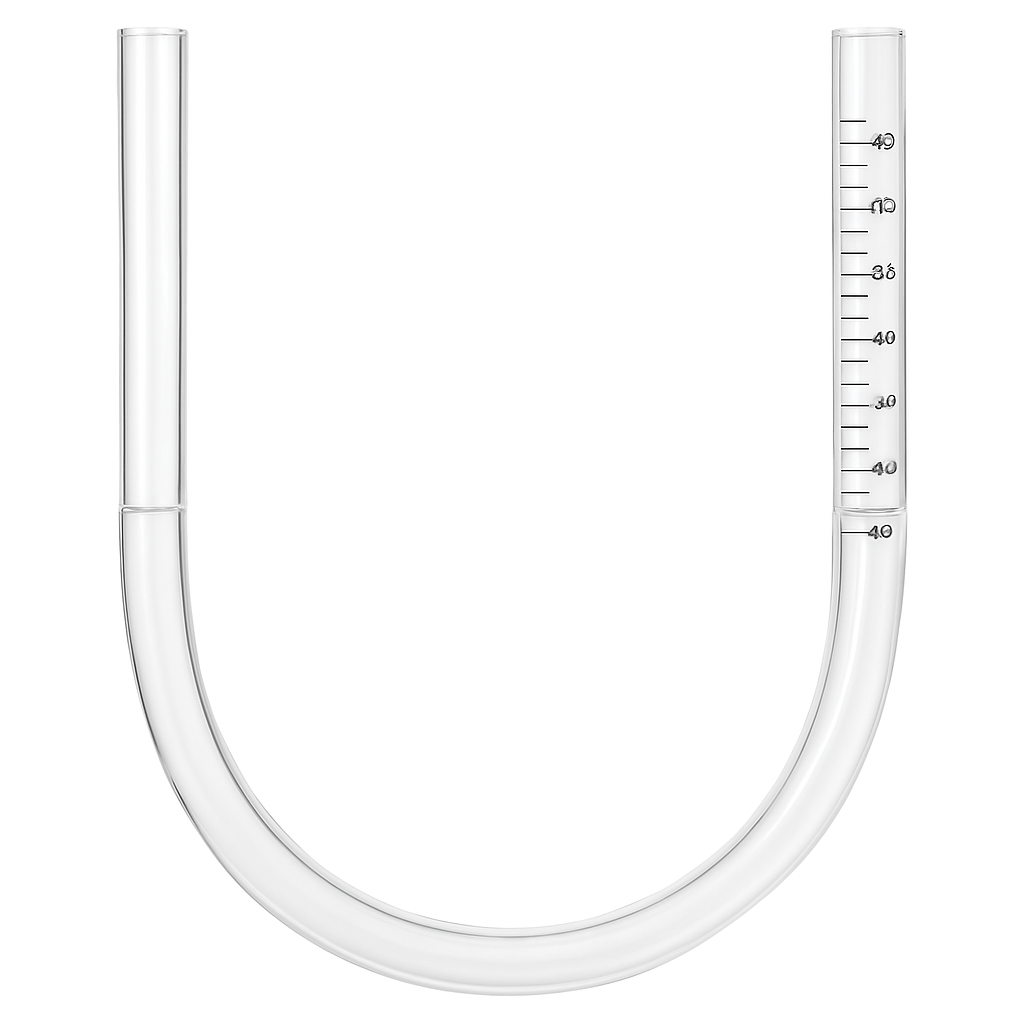

A water level, also known as a hose level, is a simple device made of a length of clear plastic tubing partially filled with water. Based on the principle that water seeks its own level, the tool allows builders to establish a common height across distant points. It’s particularly handy when levelling across corners or obstacles where direct sight lines are impossible.

Because it doesn’t rely on batteries or electronics, a water level is ideal for rural or remote sites where technology might fail, or as a reliable backup when digital tools malfunction.

To use a water level, two operators hold the ends of the tube at different points — for instance, on either end of a wall or across a large slab. By observing the height of the water in the tubes relative to each point, they can mark level benchmarks on both surfaces. These reference marks are then used to guide further construction, such as bricklaying, plastering, floor screeding or tiling.

Proper calibration is key: bubbles in the tube, kinks, or temperature-related expansion can all cause slight deviations. The tool must be held vertical at both ends and allowed to settle before readings are taken.

Despite its simplicity, the misuse or neglect of levelling — whether with a water level or other tool — is widespread. On building sites across the country, it’s not uncommon to see slabs or walls levelled by eye or “corrected” with a quick fix: throwing extra concrete into a low spot or filling gaps with mortar.

This leads to multiple problems:

• Structural integrity: Mortar used as a filler for low slab areas or as patchwork in place of concrete compromises strength. Mortar is not designed to bear load and can crumble under pressure.

• Dry joints: When fresh concrete is added to hardened or drying concrete without proper preparation, it creates a dry joint. These weak interfaces reduce monolithic performance, increasing the risk of cracking or delamination.

• Jointing and finishing: Rushed jobs often ignore proper jointing techniques. Expansion and contraction joints are either omitted or poorly placed, leading to cracks and surface failures.

If discrepancies in level are detected — ideally before pouring concrete — the correct approach is to re-establish benchmarks and recompact the substrate or adjust formwork accordingly. If concrete must be poured in phases, the use of bonding agents and keying methods are vital to avoid cold joints.

For slabs, self-levelling screeds can be used after ensuring structural concrete is correctly laid. Brands like A Shak, Sika, Chryso, and a.b.e. Construction Chemicals supply reliable bonding agents, admixtures and repair mortars suited for these jobs.

Water levels can be found at most South African hardware and builders’ suppliers.

For more advanced levelling, rotary lasers and dumpy levels are available from Lasercorp, Survey Instruments Africa and Stabila, but these come at a higher cost and require training.

While it may seem like a relic compared to digital gadgets, the water level is a fundamental tool that, when properly used, ensures accuracy, avoids costly rectification work and contributes to the long-term durability of any structure. But even the best tool is only as good as the hands that wield it — and no amount of mortar can fix a bad job done without a level head and a proper level.