On 16 June this year, it will be 10 years since Twinstar Precast opened its doors and began manufacturing custom precast products for the civil engine

On 16 June this year, it will be 10 years since Twinstar Precast opened its doors and began manufacturing custom precast products for the civil engineering and building sectors.

With a casting area of 150m², an office area which had been converted from a horse stable, only one order, a concrete mixer, two wheelbarrows and six staff members, the company took a giant leap of faith in pursuing a passion for precast concrete, specifically custom designs.

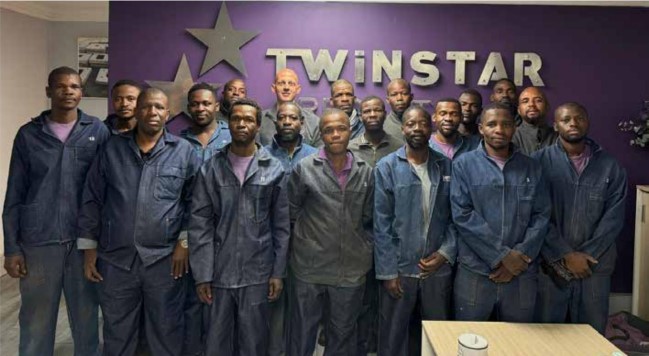

Its determination more than paid off, as the next decade of success has shown. Today, the company is acknowledged as a respected and trusted industry leader, with a reputation for expertise and excellence in both its service and products. It now has 1 150m² of casting area, an office adjacent to its factory with interlinking doors between them, four Silla concrete mixers, 18 factory staff members, one office assistant, two managers and its founder and MD Annemerie Coetzee.

From the complex….

Twinstar Precast solves the difficult, once-off jobs as well as those on complicated sites that can make civil engineering and construction challenging.

Not all building contractors have the necessary expertise, manpower or facilities to manufacture such products on site. For that reason, it is Twinstar’s express aim to assist both civil engineers and civil engineering contractors dealing with difficult worksites and situations in which using currently available precast concrete products will simply not work.

The company has specifically geared itself to undertake these types of once-off jobs, which are typically avoided by many precasters due to their complexity, size and resource-intensive nature. Customised precast products require additional effort and time to design with their once-off moulds. They can also disrupt normal production lines, due to their need for additional skills and supervision.

The company manufactures products ranging in weight from 2kg up to 6 tons. As a result of the complexity of this type of work it remains the only company in the country specialising exclusively in custom-made and one-off, unconventional precast concrete products.

Any other sizes can be manufactured on request, as Twinstar specialises in custom sizes and once-off items. Its products are known and respected throughout the construction industry for their durability, versatility, cost-effectiveness and visual appeal. They are manufactured using advanced techniques and undergo stringent quality checks before being made available to clients. The products are supplied with meticulous manufacturer’s guidelines for installation which ensure correct positioning, proper alignment and stability.

The company’s success is the result of its strong relationships within the industry, ranging from civil engineering contractors – its direct customers – to architects and specifying engineers who conceptualise requirements. It enjoys a unique relationship with mainstream precast concrete companies who pass on referrals and use Twinstar to supply certain non-standard products to keep their clients happy.

…To the conventional

Twinstar also always keep a few fast-moving products in stock which are standard specifications in tenders and drawings. Companies which previously manufactured them have either stopped or have closed down. This is another reason for Twinstar’s singular positioning in the industry as a manufacturer of products for both conventional and customised requirements of all types.

“Solving a client’s problem is what we do, no matter how big or small,” says Coetzee.

“With theft of all types of equipment rising every day in SA and the current situation, in which law enforcement is failing to curb this, we’ve been approached by numerous clients to come up with a solution to protect equipment with concrete enclosures. In response, we’ve designed and manufactured different types of enclosures to safeguard various types of equipment, such as electrical components, solar equipment and batteries.

“Some of these enclosures or bunkers have been designed by the clients and brought to us to cast and test their durability. Others have been designed by us, after a client has approached us with a problem and asked us for a solution. Still others have been designed, cast and eventually perfected by us after a client has explained a problem and requested our help. In every case, however, we’ve ensured that we’ve provided the correct product for the job and kept the client happy.”

With this type of service ethic and legacy behind it, Twinstar Precast can celebrate its 10th birthday secure in the knowledge that there will be many more decades of excellence ahead.

COMMENTS